MITNIK offers a wide range of grader blade products to choose from. 6" wide, 8" wide, 10" wide. 2 feet to 12 inches long. 1/2", 5/8", 3/4", 7/8", 1" and thicker.

We have carbide in the 500 Brinell, 550 Brinell, 600 Brinell and 1800 Brinell ranges

MITNIK steel blades are guaranteed not to break!

Most of these blades can be used in other applications, for example flat blades are often used in snow plows, wing plows or V-plows. Almost all of this section can be used on box scrapers, three-point hitches, and bulldozers. Grader blades are used for gravel road maintenance, farm earthmoving, road building and snow removal.

7T1633 Caterpillar Grader Blade-5/8"x6"x6' w/Bolts & Nuts. Caterpillar Cutting Edge Parts 5B5564 7T1633, 8-hole Caterpillar Bolt Cutting edge, High carbon and boron steel 16mm blade, custom designed Tractor double bevel curved Flater blade and edge, ground meshing Tool Spare Parts Factory

Caterpillar Cutting Edge Parts 5B5564 7T1633

Component number 7T1633/5B5564/5B-5564

7T1633 Curved Cutting Edges Fit for Caterpillar D9 compared with similar products on the market, it has incomparable outstanding advantages in terms of performance, quality, appearance, etc., and enjoys a good reputation in the market.MITNIK/MMP summarizes the defects of past products, and continuously improves them. The specifications of 7T1633 Curved Cutting Edges Fit for Caterpillar D9 can be customized according to your needs.

Heavy machinery spare parts Grader Blades Cutting Edges CAT 4T2242 4T3007 4T3036 4T2244 4T2231 4T2236, 4T2244 4T-2244 CATERPILLAR 72″ CURVED GRADER BLADE, 13 Holes 7ft Long Curved Edges fit Caterpillar Motorgrader 7D1576, 13 Holes 6ft Long CAT Double Bevel Curved Blades 5D9553

The best curved edge choice is often the impact tolerate through hardened edge. Curved edges penetrate the roadway better than flat edges while carrying existing material forward to leave a smooth even surface. 4T2236 China Heat Treated 17 Hole Grader Blade, 4T2236 4T-2236 17 Holes Cutting Edges for Grader Models 14G 14H 160H 163H.

| Applicable Industries: | Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Retail, Construction works , Energy & Mining, Other | Compatible Brand: | CATERPILLAR |

| Model/Part No.: | 7T1633 | Material: | Carbon HRC280-320HB-Standard Boron HRC440-520HB-Good Quality |

| Hardness: | HB440~480 | Yielding Point: | 1440N/mm2 |

| Working hours: | 4000-6000hrs | Technique: | Forging |

| Suitable: | Bulldozer/Wheel Loader/Grade Motor | Warranty: | 12-24Months |

| Color+Logo: | Yellow or As required And Logo Customized | Packing: | Plywood Pallet with wrapping/Customization |

Grader blades:

| P/N | Dimension(mm) | Holes | Bolt size | P/N | Dimension(mm) | Holes | Bolt size |

| 5D9553 | 1828X152X16 | 13 | 5/8″ | 4T2231 | 1828X203X25 | 13 | 3/4″ |

| 5D9554 | 2133X152X16 | 15 | 5/8″ | 4T2233 | 2133x203x25 | 15 | 3/4″ |

| 5D9558 | 1828X203X19 | 13 | 5/8″ | 4T2237 | 2438x203x25 | 17 | 5/8″ |

| 5D9559 | 2133X203X19 | 15 | 5/8″ | 5B5564 | 1828x152x16 | 8 | 5/8″ |

| 5D9561 | 2133X203X16 | 15 | 5/8″ | 5B5562 | 2133x152x16 | 9 | 5/8″ |

| 5D9562 | 1828X203X16 | 13 | 5/8″ | 9W2301 | 2438x152x13 | 10 | 5/8″ |

| 7D1577 | 2133X203X19 | 15 | 3/4″ | 9W2299 | 2133x152x13 | 9 | 5/8″ |

| 7D1949 | 2438X203X19 | 17 | 3/4″ | 9W2302 | 2438x152x13 | 10 | 3/4″ |

| 7D1588 | 2133X203X16 | 15 | 3/4″ | 9W2309 | 1219x203x13 | 6 | 5/8″ |

| 4T2244 | 1828X203X25 | 13 | 5/8″ | 8J9821 | 2438x203x16 | 17 | 3/4″ |

| 4T2242 | 2133X203X25 | 15 | 5/8″ | 9W2297 | 1828x152x13 | 8 | 5/8″ |

| 4T2236 | 2438X203X25 | 17 | 3/4″ | 234-70-12670 | 2133x203x19 | 15 | 5/8″ |

| 9J3658 | 2133X152X16 | 15 | 3/4″ | 234-70-12710 | 2133x203x16 | 15 | 3/4″ |

| 7D4508 | 1524X152X16 | 11 | 5/8″ | 234-70-12193 | 2133x152x16 | 15 | 5/8″ |

| 5D9556 | 1828X152X19 | 13 | 5/8″ | 4T3036 | 2133x203x19 | 15 | 5/8″ |

| 5D9557 | 2133X152X19 | 15 | 5/8″ | 4T3007 | 1828x203x19 | 13 | 5/8″ |

| 3G7966 | 1524X152X19 | 11 | 5/8″ | 4T3034 | 1524x203x19 | 11 | 5/8″ |

| 9J3657 | 1828X152X16 | 13 | 3/4″ | 4T3037 | 2438x203x19 | 17 | 3/4″ |

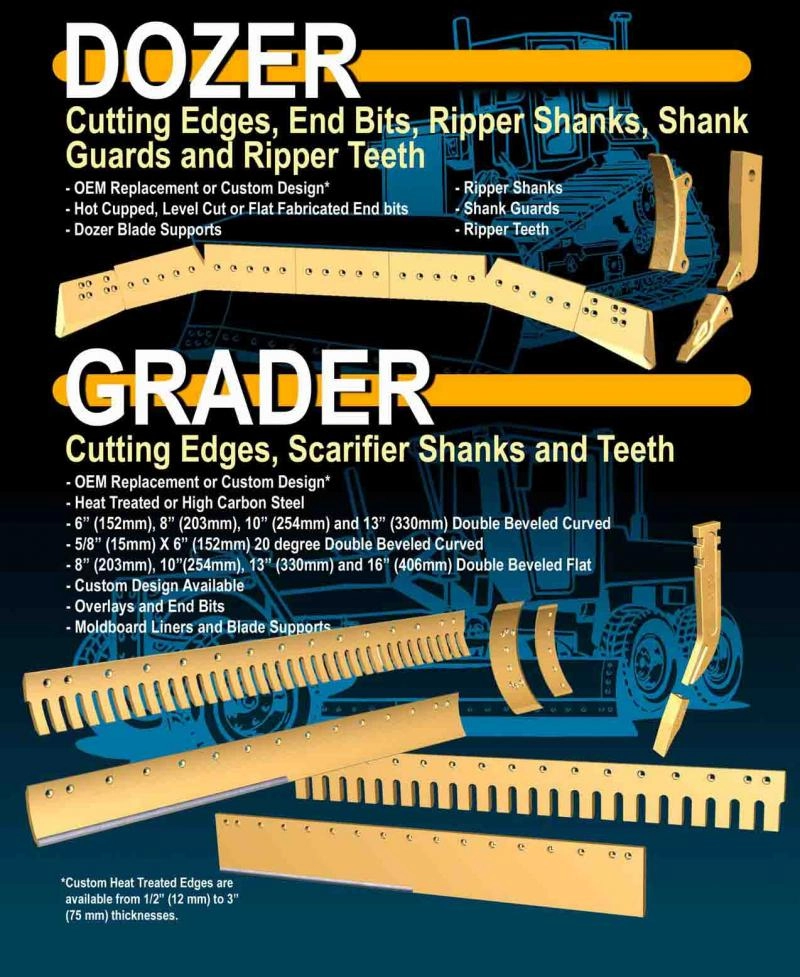

MITNIK MACHINE PARTS with OEM&ODM for all kinds of Cutting Edges/Blades/End Bits:

MITNIK offers a variety of cutting edges are available for graders. Each provides certain benefits when used in the appropriate application. Using the right edge is critical to increasing production and minimizing overall costs. Three factors to consider when selecting a cutting edge are shape, width and thickness.

MITNIK MACHINE PARTS Motor Grader Blades manufactured from Boron Steel Alloy are heat treated and tempered to exact specifications to ensure the best combination of wear and impact resistance.

There are two basic edge shapes—flat and curved—with both configurations offering serrated edges. Additionally, the Cat GraderBits system greatly expands the range of edge shape options. Cat offers two types of grader edges and three edge thicknesses for the 16M and 24M graders.

Edge selection is critical for enhancing production and keeping cost to a minimum. Application affects the cutting edge shape, metallurgy and style. Impact, penetration and abrasion define your application environment. An edge has to penetrate the material and not break during operation. Edge life then becomes a matter of metallurgy and thickness.

MITNIK Cutting Edge system ensures your machines are as effective and efficient as your application demands. Choose the features you need to match your needs and get the results you want.

MITNIK Precision Cutting Edges: For optimising your blade investment

MITNK FirstCut Cutting Edges: For your most demanding applications

MITNIK High Abrasion Cast Cutting Edge System: For your most abrasive applications

• Up to 35%* increased payload

• Up to 17%* productivity improvement

• 2x more wear life*

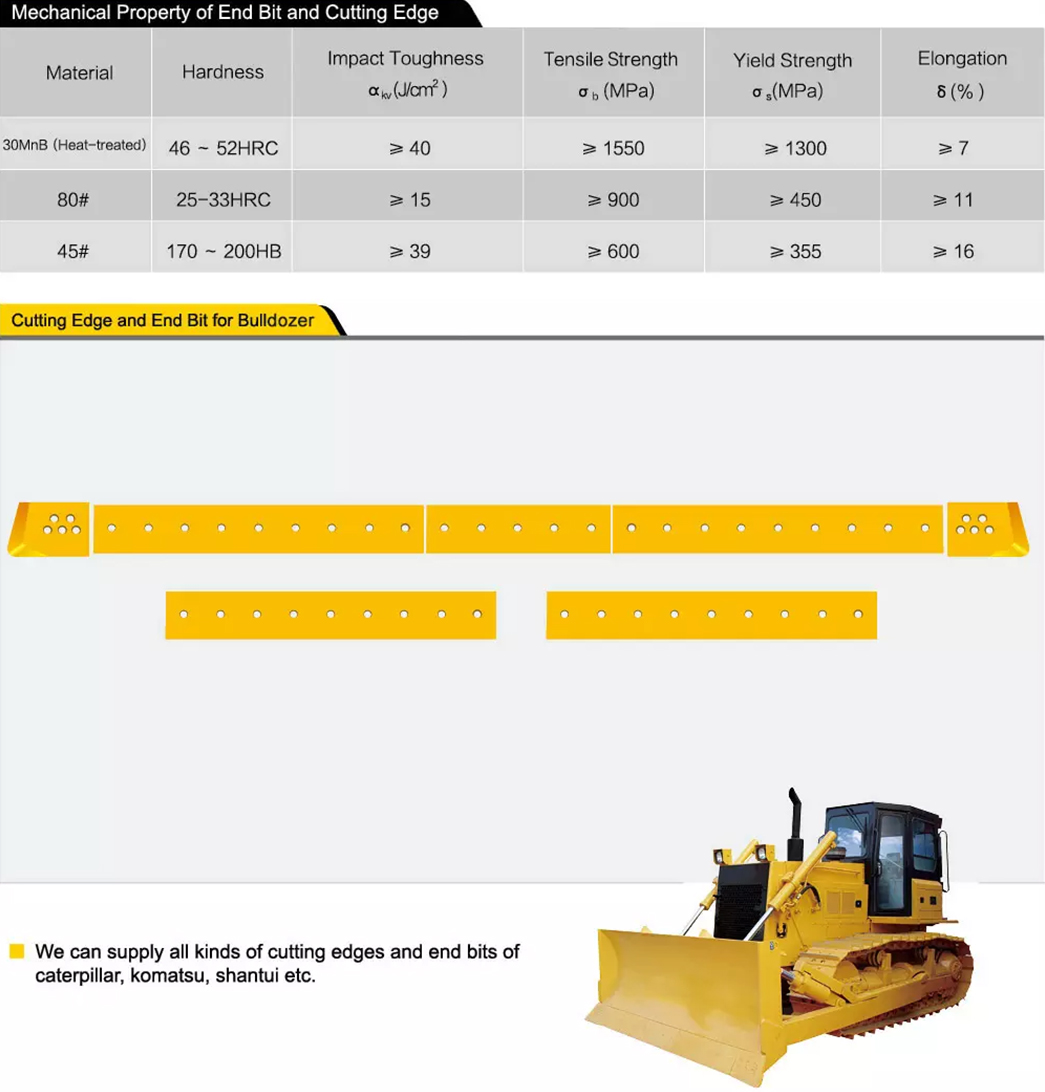

Mitnik can supply all kinds End Bit and Cutting edge of Caterpillar, Komatsu, Shantui etc....

MITNIK Edge selection is critical to increasing yields and minimizing costs. Application affects cutting edge shape, metallurgy and style. Impact, penetration and wear define your application environment. The edges must penetrate the material and not break during operation. Edge life then becomes a matter of metallurgy and thickness.

FLAT

» Heavy road maintenance and pioneering

» Maximum strength and available wear material

» Best option for abrasion and impact resistance

FLAT SERRATED

» Better penetration than a continuous edge (greater down pressure per inch of edge contact)

» Designed to penetrate packed gravel, frozen earth and ice

» For severe impact conditions, install over a 6" (152 mm) edge to reduce tooth breakage

CURVED

» Provides superior penetration and rolling action necessary for fine grading and finish work

» Finishing tolerances less than 1/4" (6 mm)—the best value may be in selecting a narrow and thin cutting edge

CURVED SERRATED

» A curved serrated edge penetrates better than a straight serrated edge with a forward mold board

EDGE WIDTH EQUALS WEAR MATERIAL

» An 8" (203 mm) edge provides twice the wear material as a 6" (152 mm) edge at about 35% more cost

» Hardware cost and R&I downtime are reduced by 50%

MITNIK TUNGSTEN CARBIDE TILE CUTTING EDGES

Tungsten Carbide Cutting Edges combine through-hardened steel with the wear resistance of tungsten carbide. When used in high-abrasion, low-impact applications, they can provide up to 20 times the life of a standard through-hardened edge. Fewer edge changes means less downtime and lower hardware costs.

TUNGSTEN CARBIDE EDGES

» Tungsten carbide edges have a continuous row of trapezoid-shaped carbide “tiles." This patented shape forms a leading / cutting edge

» Carbide tile bottom must be flat to the ground. 20° maximum tilt

» Max 5 mph/8kph

» Do not use on roads with large embedded rocks

FLAT EDGES

» Maximum strength and available wear material

» Longest wearing edge available in high abrasion and low impact

CURVED EDGES

» Curved-edge design improves penetration and rolling action

» Trapezoid-shaped tungsten carbide tile on leading edge stays sharp as it wears

» Shorter edge sections speed rotation and reduce “throw-away" due to edge crowning

SERRATED EDGES

» Better penetration than a continuous edge (greater down pressure per in of edge contact)

» No cast angle restrictions

MITNIK MACHINE PARTS is the worldwide leader Bulldozer & Excavator Undercarriage Manufacturer in replacement parts and original parts and accessories for Engineering Machine, Construction Machine, Industrial Truck and Agricultural Equipment over 20 years old, and MITNIK can do OEM&ODM for engineering machine parts. Our mission is to provide excellent products and service to our customers, at competitive prices. We stock an extensive range, so, whether you are looking for a single tractor part or wholesale replacement parts MITNIK MACHINE PARTS has it covered. MITNINK MACHINE PARTS-MMP is an excellent source for original and aftermarket components and parts. We can provide the main major road construction machine parts and excavator&bulldozer parts. MITNIKMACHINEPARTS-MMP is an excellent source for used, rebuilt, refurbished and aftermarket components and parts. We can provide the main major road construction machine parts and excavator&bulldozer parts brands such as: Komatsu Caterpillar Volvo JCB Terex. Kobelco Hyundai Doosan John Deere Hitachi Takeuchi Sanyi MITNIK MACHINE PARTS, new spare parts range for heavy construction equipment focuses on excavator&bulldozer undercarriage, engaging tools, engine parts, hydraulic parts, dump truck parts, concrete machine parts. Within those spare parts, key attention lies on parts for the makes Bobcat, Case, Caterpillar, JCB, Takeuchi, John Deere, Kubota, Volvo and Yanmar etc...., while also offering extensive lookup services for other brands. We have more than 3 million parts on hand across more than 30,000 different part types covering all makes and models. MISSION MITNIK MACHINE PARTS-MMP to offer integrated and value-added part supply and full lines of equipment parts solution to our partners and customers with assuranced quality parts. SERVICE MITNIK MACHINE PARTS-MMP with one-stop shopping platform for engineering construction machinery parts as MITNIK have our own factory and storage warehouse and some parts of them were supply by our Joint Stock Partnership to ensure to provide excellent products and service to our customers, at competitive prices. To offer an excellent source for used, rebuilt, refurbished and aftermarket components and parts. We can provide Construction Machine, Heavy Equipment, and related Equipment Parts sucha as road construction machine parts and excavator&bulldozer parts etc..... QUALIFEID Our company has established a complete quality control system. We have several labs with all kinds of Mechanic & Chemical Property Testing Equipments. We do IQC, IPQC, FQC to guarantee our quality. Our company are certified ISO9001:2008,ISO14001:2004 and OHSMS18001. We have won many honors, such as “ Product and Service Recommended Enterprises”,“Quality Management Advanced Enterprise”, etc.

MITNIK MACHINE PARTS is the worldwide leader Bulldozer & Excavator Undercarriage Manufacturer in replacement parts and original parts and accessories for Engineering Machine, Construction Machine, Industrial Truck and Agricultural Equipment over 20 years old, and MITNIK can do OEM&ODM for engineering machine parts. Our mission is to provide excellent products and service to our customers, at competitive prices. We stock an extensive range, so, whether you are looking for a single tractor part or wholesale replacement parts MITNIK MACHINE PARTS has it covered. MITNINK MACHINE PARTS-MMP is an excellent source for original and aftermarket components and parts. We can provide the main major road construction machine parts and excavator&bulldozer parts. MITNIKMACHINEPARTS-MMP is an excellent source for used, rebuilt, refurbished and aftermarket components and parts. We can provide the main major road construction machine parts and excavator&bulldozer parts brands such as: Komatsu Caterpillar Volvo JCB Terex. Kobelco Hyundai Doosan John Deere Hitachi Takeuchi Sanyi MITNIK MACHINE PARTS, new spare parts range for heavy construction equipment focuses on excavator&bulldozer undercarriage, engaging tools, engine parts, hydraulic parts, dump truck parts, concrete machine parts. Within those spare parts, key attention lies on parts for the makes Bobcat, Case, Caterpillar, JCB, Takeuchi, John Deere, Kubota, Volvo and Yanmar etc...., while also offering extensive lookup services for other brands. We have more than 3 million parts on hand across more than 30,000 different part types covering all makes and models. MISSION MITNIK MACHINE PARTS-MMP to offer integrated and value-added part supply and full lines of equipment parts solution to our partners and customers with assuranced quality parts. SERVICE MITNIK MACHINE PARTS-MMP with one-stop shopping platform for engineering construction machinery parts as MITNIK have our own factory and storage warehouse and some parts of them were supply by our Joint Stock Partnership to ensure to provide excellent products and service to our customers, at competitive prices. To offer an excellent source for used, rebuilt, refurbished and aftermarket components and parts. We can provide Construction Machine, Heavy Equipment, and related Equipment Parts sucha as road construction machine parts and excavator&bulldozer parts etc..... QUALIFEID Our company has established a complete quality control system. We have several labs with all kinds of Mechanic & Chemical Property Testing Equipments. We do IQC, IPQC, FQC to guarantee our quality. Our company are certified ISO9001:2008,ISO14001:2004 and OHSMS18001. We have won many honors, such as “ Product and Service Recommended Enterprises”,“Quality Management Advanced Enterprise”, etc.

Please verify part number prior to order.

Thanks for viewing our listings. Please click "Ask A Question", or call us if you have a parts need that you do not see listed here.

We will do our best to locate the parts you need, and make every effort to save you money.

For parts information in English please CONTACT US

LEAVE US A MESSAGE

MITNIK MACHINE PARTS is the worldwide leader in replacement parts and original parts and accessories for Engineering Machine, Construction Machine, Industrial Truck and Agricultural Equipment

© 2003-2022 MITNIK MACHINE PARTS-All Rights Reserved